The application is designed to monitor stamping machines using a video camera. A single stamping machine cycle passes from 0° to 360° at speeds of up to 200 strokes per minute. The application can warn the operator or stop the machine automatically if something changes significantly from the expected normal production process. The application requires no specific machine state detection, it is not waiting for, detecting, or relying on a specific, repeatable machine state before it starts its analysis. It provides continuous monitoring and requires no phase-coupling between the machine and the video stream. It operates agnostically of the machine’s phase or any specific trigger. Limited only by speed of the camera and the hardware used to analyse the video feed, the system attempts to detect potential problems as soon in the machine’s production cycle as possible.

How it works

Training (Learning What’s Normal):

- Showing the Application What’s Normal: First, the program watches several cycles of a video stream of the machine and production process working normally.

- Learning to Recreate Normal: The program then learns to identify patterns and features of what it expects the machine to look like at the next frame.

Inference (Detecting Problems / Defects):

- Watching for Deviations: When the machine is working, the program continuously monitors the live video feed.

- Predicting and Comparing:

- It compares the actual live video frame to its own expectation.

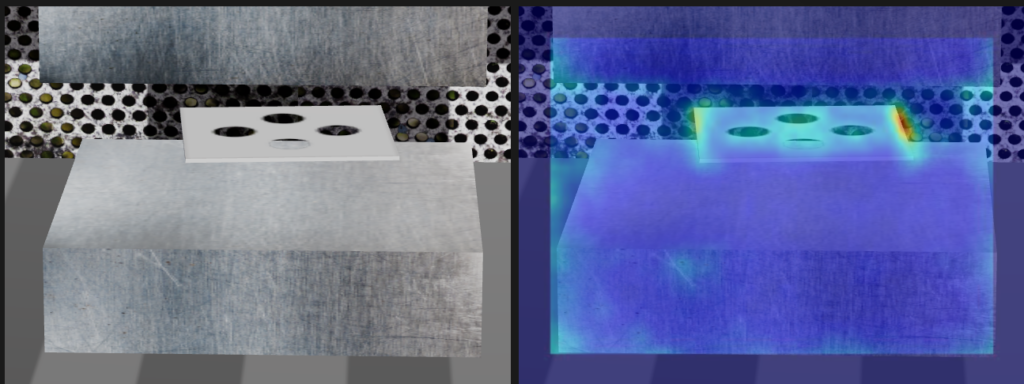

- Finding the “Faults”:

- If there’s a big difference between what it sees and what it expects, it means something unusual is happening.

- The program then examines these differences closely and highlights bright spots where things don’t match.

- It then differentiates between just minor “noise” (like a tiny flicker) or significant “fault” changes. It has a scoring system to measure how bad the fault is.

- Alerting: If the “fault score” goes above a certain level, the program immediately stops the video and highlights the problem area, effectively indicating that something unexpected happened. This can include a visual warning for a machine operator and / or a stop signal to the stamping machine.

The core of our design lies in the data processing and algorithmic approach, which avoids a patented method of comparing a captured image from a defined operating state with a stored reference image or model specific to that state.

Using Unsupervised Anomaly Detection our approach avoids a patent’s deterministic comparison.

- Training: The method uses models trained exclusively on data collected during normal machine operation. This “normal” data comes from image sensors however the subsequent processing logic is different.

- Mechanism: The system learns a compact representation or statistical model of “normality.” The model learns to reconstruct normal input data with low error. When anomalous data (deviating from normal patterns) is fed in, the reconstruction error will be significantly higher.

Anomaly Decision: An anomaly is flagged if the reconstruction error exceeds a set threshold. This threshold can be determined statistically from the distribution of scores on normal data.